- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-02-13 Origin: Site

Shredding thick plastic materials is a critical process in industries such as recycling, manufacturing, and waste management. However, safely and efficiently shredding these materials requires the use of the right equipment, such as a two shaft shredder, and adherence to safety protocols. This article will explore best practices for shredding thick plastic materials, focusing on how to do so safely, efficiently, and effectively.

Thick plastic materials, such as large plastic sheets, pipes, or rigid plastic components, present unique challenges in shredding operations. These materials are often tough, dense, and resistant to cutting, which can lead to mechanical stress on the shredder, potential blockages, and inefficient processing. Without the right equipment and methods, shredding thick plastic can lead to increased wear on machinery, higher energy consumption, and safety hazards.

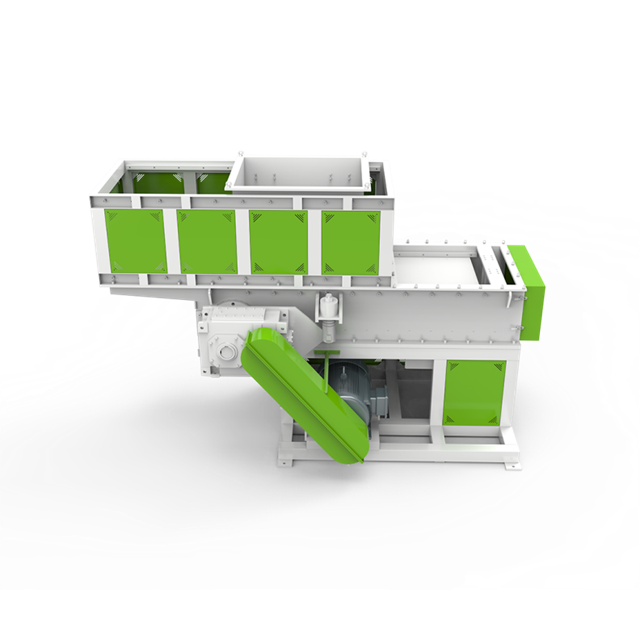

A two shaft shredder is an excellent choice for handling thick plastic materials due to its robust design and versatility. Unlike single-shaft shredders, two shaft shredders feature two rotating shafts with interlocking blades that work together to tear through tough materials. This design is particularly effective in reducing thick plastic to smaller, manageable sizes without causing the machine to overheat or jam.

The synchronized rotation of the shafts allows the shredder to handle a variety of thick plastic materials, including hard plastics, pipes, and large plastic sheets. The interlocking blades grip and pull the material into the shredder, ensuring consistent shredding without the risk of material bouncing out or clogging the machine.

Two shaft shredders are built with durable components designed to withstand heavy-duty tasks. The tough blades and heavy-duty shafts ensure that even the thickest plastic materials can be processed without causing damage to the shredder. This durability is essential for maintaining the long-term efficiency of the shredder and reducing maintenance costs.

Choosing the right shredder for thick plastic materials is essential for both efficiency and safety. While a two shaft shredder is ideal for many types of thick plastics, it’s important to select a model with the right specifications for the material you’re shredding. Consider factors such as:

Shredder capacity: Ensure that the shredder is capable of handling the volume of material you need to process. High-capacity shredders can handle larger batches of thick plastic efficiently.

Blade configuration: Some materials may require specialized blades or configurations to ensure a clean and efficient cut. For example, harder plastics may require stronger, sharper blades.

Throughput speed: The speed of shredding impacts both the efficiency and safety of the operation. A shredder with adjustable speed settings can be beneficial for managing various plastic thicknesses.

Routine maintenance is critical to the safe operation of shredders, especially when processing thick plastic materials. Regular checks and adjustments help maintain optimal shredding performance and prevent breakdowns. Key maintenance tasks include:

Blade sharpening and replacement: Dull blades can cause inefficient shredding and put additional stress on the machine, increasing the risk of jamming or overheating. Regularly inspect and sharpen or replace the blades as necessary.

Lubrication of moving parts: Shredders contain moving components that require regular lubrication to prevent wear and overheating. Ensure that the lubricant used is suitable for high-load operations.

Checking for blockages: Before starting a shredding cycle, always check the shredder for any material buildup or blockages. Keeping the machine clear of debris ensures smooth operation and minimizes the risk of jams.

Safe and efficient shredding also depends on how the material is loaded into the machine. Proper loading techniques help prevent jams and reduce wear on the shredder. Follow these tips for safe material loading:

Avoid overloading the shredder: Overloading the shredder with thick plastic materials can strain the machine and increase the risk of jams or motor failure. Feed the material gradually and monitor the shredder’s performance.

Pre-cut large pieces: For large plastic sheets or bulky items, it may be necessary to pre-cut the material into smaller sections before feeding it into the shredder. This helps the machine handle the material more effectively and reduces the risk of blockages.

Evenly distribute material: When feeding materials into the shredder, make sure they are distributed evenly to avoid sudden surges in load that can cause the motor to strain or overheat.

Constant monitoring of the shredder’s performance is essential for safe operation. Check for any signs of overheating, unusual noise, or excessive vibration, which can indicate issues with the shredder’s components. Use monitoring tools such as temperature gauges, vibration sensors, and pressure indicators to detect early warning signs of potential problems.

Safety should always be a top priority when operating a shredder. Many modern two shaft shredders come equipped with safety features such as automatic shutdown mechanisms, emergency stop buttons, and protective covers. Always ensure that operators are fully trained on how to use these safety features and follow proper safety protocols, including:

Personal protective equipment (PPE): Operators should wear appropriate PPE such as gloves, safety goggles, and hearing protection when operating the shredder.

Lockout/tagout procedures: Before performing maintenance or cleaning, always follow lockout/tagout procedures to ensure the machine is completely powered down and cannot be accidentally started.

Shredding thick plastic materials safely and efficiently requires the right equipment, proper maintenance, and adherence to best practices. The two shaft shredder is an excellent choice for handling these challenging materials, offering durability, efficiency, and consistent performance. By following best practices for material loading, maintenance, monitoring, and safety, you can ensure that your shredder operates effectively, reduces downtime, and extends its lifespan.

Investing in the right shredder machine and implementing safe shredding practices will not only improve the efficiency of your plastic recycling or processing operation but also ensure the safety of operators and minimize the risk of costly machine breakdowns.